- +91 9511117684

- shweta@dataman.in

Increase Productivity – Key is Material Management Software

Table of Contents

Post Views: 8,449

What is Construction Material Management software ?

In the construction industry, material management software can play a crucial role as projects have to be completed on time for greater revenue generation, maximizing profits and for attaining long term growth and success.

Material management in Construction refers to carrying out all activities related to materials which add value to the finished products.

According to the International Federation of Purchasing and Materials Management, “materials management is a total concept having its definite organization to plan and control all types of materials, its supply and its flow from raw stage to finished stage so as to deliver the product to customer as per his requirements in time.

Some Key aspects of Material Management are :

- Planning & Procurement of material

- Storage & Inventory Management

- Quality Control & Inspection

- Transportation and Distribution of materials safely and efficiency

- Waste Reduction

Objectives of Material Management

The main objectives of material management often known as famous 5 R’s of material management are acquisition of materials & services of :

- The right quality of supplies

- The right quantity of supplies

- At the right time

- At the right place

- At the right price

Also read: Exploring Concrete Mix Ratios for Different Purposes

What is Material Management Software?

Material Management Software is a smart digital tool or software application designed to streamline all operations like inventory control, procurement, warehouse management, supply chain operations etc.relevant to managing materials within any construction / real estate, healthcare, manufacturing, wholesale, retail, Government agencies, universities, hotel industry & so on.

The primary objective of MMS application is to improve efficiency and accuracy of handling materials throughout their life cycle from procurement to production, distribution, logistics to utilization stage.

Who requires Material Management Software?

Material Management Software is useful for all organizations across various industries especially those managing long supply chains, large inventories, those who need to optimize stocks, cut down costs or streamline their operations like real estate, manufacturing, distribution and logistic companies.

A detailed break – up of beneficiaries of Material Management Software

Manufacturers

Manufacturing Companies can use material management applications to track inventory, manage raw – materials / bills of material, order processing etc. to optimize manufacturing process

Construction Industry

Construction companies to track materials, optimize utilization of available

Resources, procuring raw – materials, cost control, supply management etc.

Wholesalers / Retailers

Wholesale and retail people can use material management software to

manage inventory, track stock status, digitise purchase processes, maintaining optimal stock levels neither overstocking or running out of stock

Distribution & Supply Chain

Distribution & Supply Chain Management Companies can go for material

management tool to track shipped orders, materials and ensure products timely delivery

Hotels & Restaurants

Hospitality industry people to manage their raw-material stocks, optimise

wastes due to overstocking & spoilage, timely delivery of services and increased guest satisfaction

R & D / Scientific Establishments

Research & Scientific establishments can use material management software

to manage and track their inventories regarding chemicals, equipment and technical devices etc.

Healthcare Organizations

Hospitals, clinics and other health care bodies often need such software to maintain essential inventory levels, track expiration dates and streamline operations.

Various government agencies, universities etc. also have a need for a material management system.

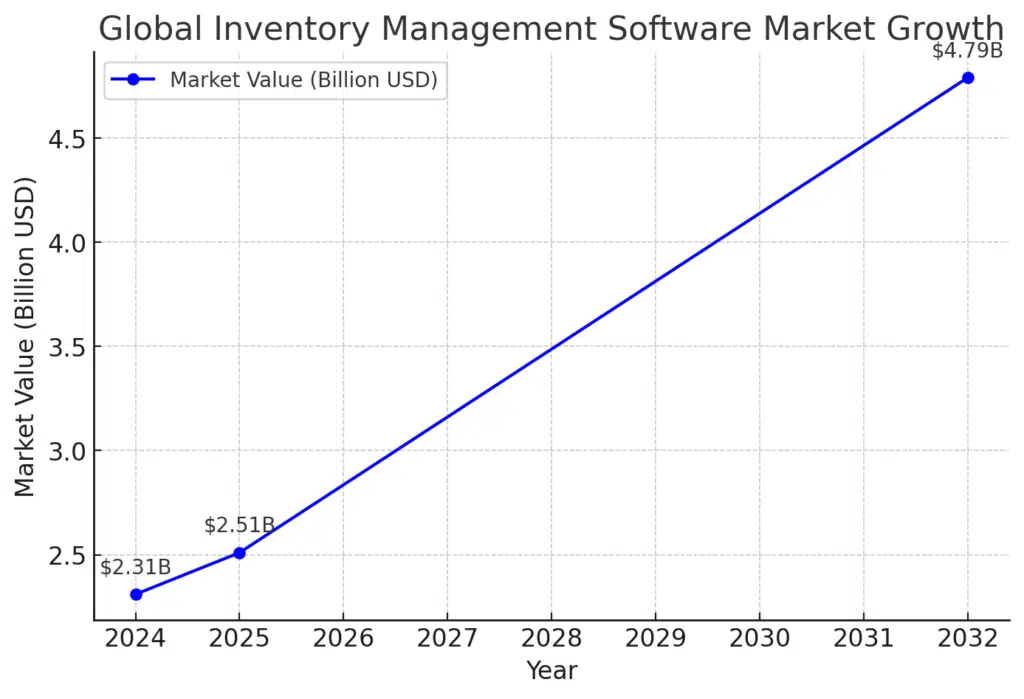

Also read : It is estimated that the global inventory management software is projected to be worth $2.51 billion in 2025 and will reach $4.79 billion by 2032, exhibiting a CAGR of 9.6%. The market was valued at USD 2.31 billion in 2024.

North America heads the global inventory management software market with a major share of over 40% in 2024.

Also refer to : Based on end user, the market is divided into manufacturing, wholesale, retail, healthcare and life sciences, hospitality, automotive and others. The manufacturing sector dominated the material management software market in 2024 having a share of about 27% followed by healthcare and retail industry.

Benefits & Key Uses of Material Management Software

Material Management Software offers a plethora of advantages for all businesses like inventory management at all levels, improved efficiency, wastage reduction, effective quality & cost control, enhanced productivity etc. A detailed overview of beneficial uses is 🎉

- Improved Inventory levels

AI feature helps to optimize inventory levels avoiding overstocking or running out of stock & ensuring customer satisfaction, reducing carrying costs and wastage

- Quality Management

Ensures that only high quality materials are used in construction processes through its real time tracking feature

- Higher Productivity

Takes care that right material in right quantity & right time is available when needed thus preventing work delays and maximize productivity

- Greater Coordination among Departments & many Warehouses

The material software facilitates better coordination among various departments and multiple warehouses for materials supply when needed

- Enhanced Customer Satisfaction

By delivering requisite orders on time to customers, this application leads to happy and loyal customers

- Improved Supplier Relationships

Accelerates faster communication and coordination with suppliers regarding materials thus improving supplier relationships and lead to better pricing and terms

- Reduced Costs & Improved Efficiency

The material management software significantly reduces operating costs by optimizing inventory, reducing waste and streamlining all processes thus leading to increased workflow efficiency

Key Uses

Purchase Management

Facilitates all purchase processes like procuring materials from suppliers at better prices, timely procurement from vendors etc.

Material Requirement Planning (MRP)

Tells about precise labour and supply requirement to avoid time

misinterpretation and less production yield

Automated Materials Reordering

Automatically triggers reordering of stocks / inventory when certain limits are reached

Managing Warehouses

The material management software leads to optimizing warehouse operations like space usage, stock holding and material handling

Just in Time (JIT) Inventory Management

Supports Just in Time / Lean Inventory Management thus avoiding

Overstocking, handles reorder points and judiciously use warehouse space

Future Demand Analysis

The material management application enables predicting future material demand based on historical data and predictive analytics to optimize inventory levels

Serial Traceability Feature

Tracks the movement and history of materials thus useful in organisations having specific regulatory requirements

Reporting and Accessing Abilities

This software provides reporting and accessing abilities to check out

material management performance, stock limit, inventory levels, warehouse operations etc.

Integration with other systems

Material Management tool integrates with other enterprising systems such as ERP (Enterprise Resource Planning) Systems, accounting software and logistics system for seamless data exchange and process synchronization

Real Builder – our Comprehensive real estate Erp solution is best fit for managing materials for all successful businesses be it real estate sector or others.

Conclusion

Thus we can conclude by saying that Material Management Software is a pivotal tool for most organizations these days to speed up their work efficiency, increase productivity, reduce costs and wastage, quality control, optimizing inventory levels, on time order delivery, production planning and future demand forecasting to be the leader in their business sphere.

Also Read: Work Order in the Construction Industry

FAQs

What is Material Management Software ?

Material Management Software is an ERP solution for handling materials in an organization for streamlining all processes starting from inventory management, procurement and purchase etc.

Who can Use Material Management Software ?

Basically manufacturing, construction, distribution & logistics companies, wholesalers, retailers, healthcare organizations, government agencies & so on

What are the Key features / Benefits of Material Management Software ?

Material management software improves inventory accuracy, reduces costs and wastage, enhances customer satisfaction, better supplier relationships, for quality control etc.

Is Material Management Software Available on the Cloud ?

Yes, it is widely available as cloud based software system for tracking inventory, purchase & supply management, easily accessible from anywhere having an internet connection.

0